編者按:日前,國際電力行業知名刊物《Power》刊登題為“模塊化發電廠正在提高肯尼亞地熱效率”的文章,向全球介紹我集團首創的地熱井口電站技術及其成就。這是繼新華社、《人民日報》等中國央媒介紹開山在肯尼亞取得的成就之后,又一個國際級媒體的推介。

《Power Magazine》在全球電力行業具有顯著的影響力。作為全球最古老的能源行業期刊之一,自1882年創刊以來,已成為電力行業內的重要信息來源和行業標準。其影響力既源于權威性和歷史性,還因為其擁有廣泛的受眾群體,讀者涵蓋了全球電力行業專業人士,包括電力工程師、運營經理、技術專家、決策者和企業高管,它通過提供深入的技術分析、案例研究和行業新聞,幫助專業人士做出更好的決策和理解行業動態。《Power Magazine》在全球電力行業扮演重要的角色,既是信息傳播的重要渠道,也是行業趨勢和技術發展的風向標,該刊物宣介開山地熱井口模塊電站技術標志著我集團擁有自主知識產權的核心技術得到業內主流媒體的認同,也料將極大地推動開山技術在全球的應用。

下面是本編輯部轉發的新聞鏈接和轉載文章的中英文對照文本,以饗讀者。

原文鏈接:https://www.powermag.com/a-modular-power-plant-is-steaming-up-kenyas-geothermal-efficiency/

A Modular Power Plant Is Steaming Up Kenya's Geothermal Efficiency

Sosian Menegai during the commissioning phase. Courtesy: Kaishan Group

Sosian Menengai Geothermal Power, Kenya’s newest geothermal power plant, is powered by modular technology that maximizes efficiency, reduces costs, and enhances scalability.

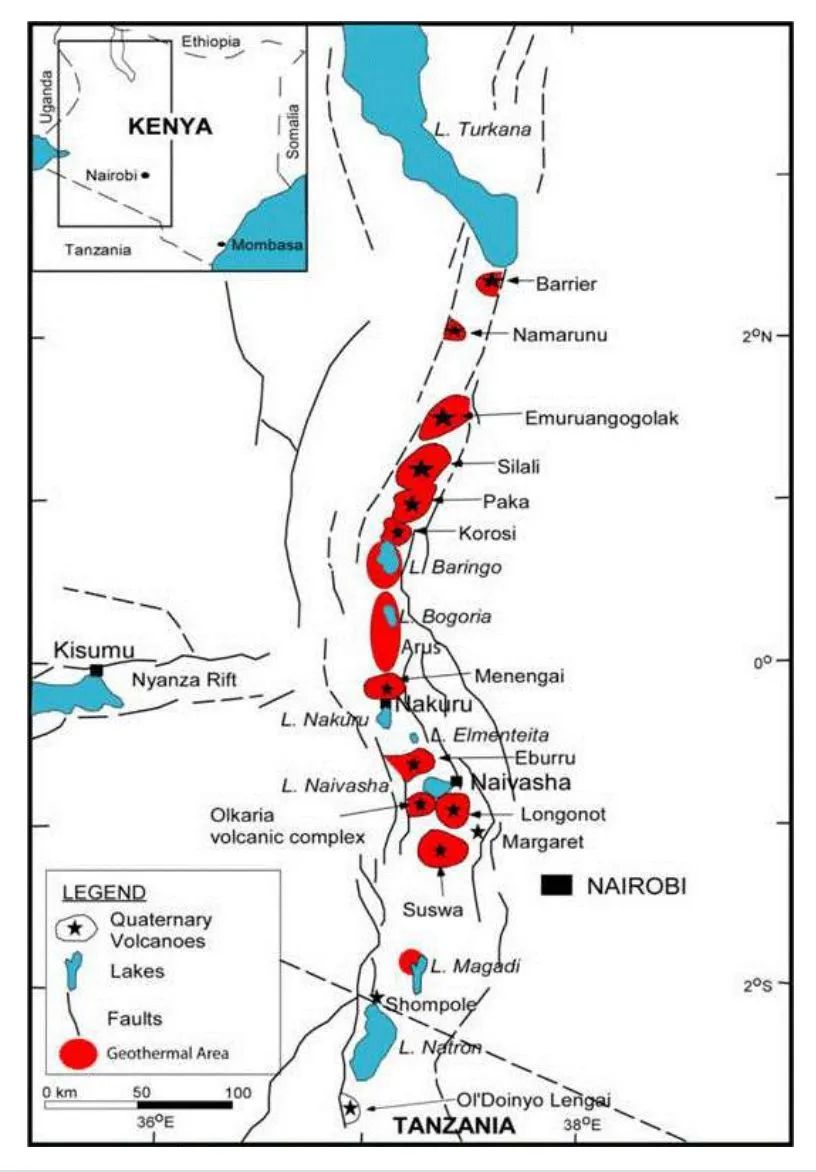

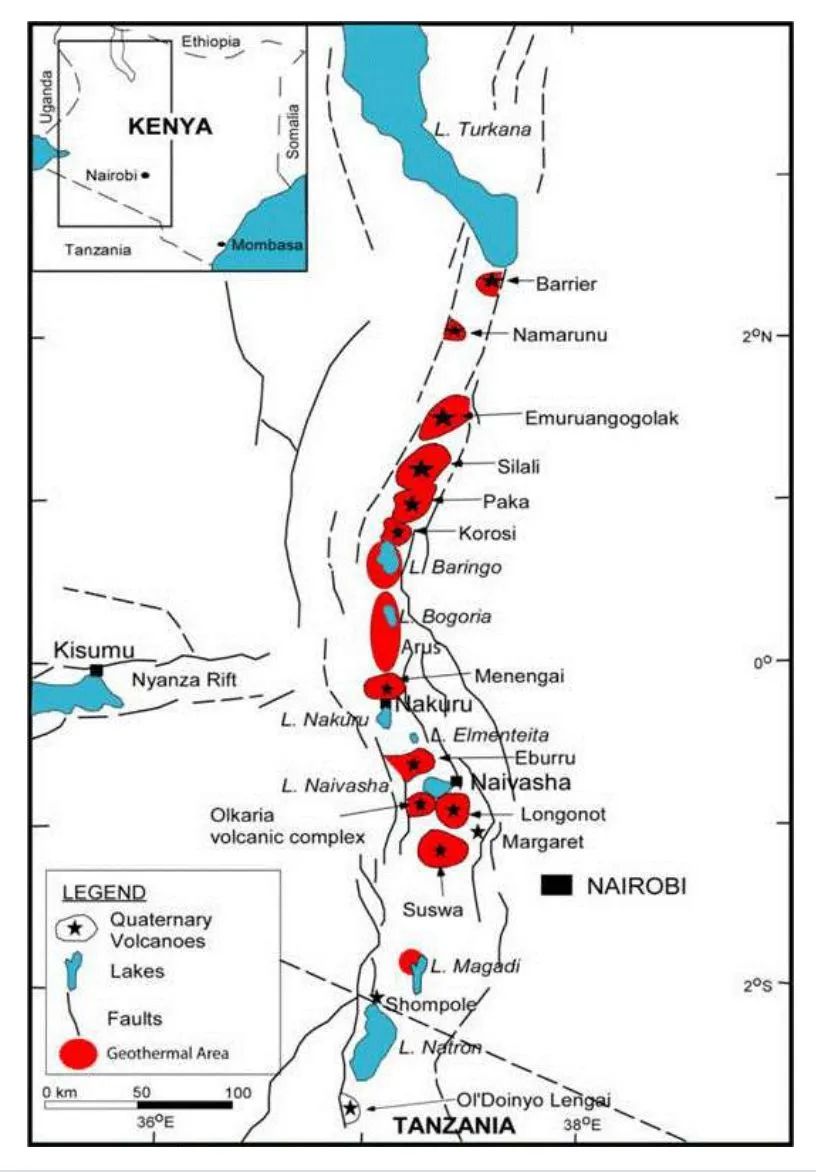

Kenya’s scenic Rift Valley region is a literal hotbed of geothermal potential. Part of the vast East African Rift Valley System (EARS), a 6,400-kilometer (km) tectonic divergence that is cleaving the African continent into two plates, Kenya’s Rift Valley forms a vertical corridor of intensive faulting and volcanic activity, hot springs, fumaroles, and sulfur-oozing fissures. But while the country began geothermal exploration for power development in the 1950s, most of its investments have been focused on the Olkaria region situated within Hell’s Gate National Park near the flamingo-flecked Lake Naivasha in Nakuru County. Five of six geothermal power stations in Olkaria are owned by KenGen (with a combined capacity of 799 MW), while Nevada-based Ormat Technologies owns a 150-MW plant. Olkaria plants in 2023 provided nearly 45% of Kenya’s total generation, a sizeable contribution to the East African powerhouse’s meager 3.3-GW installed capacity.

In 2008, the Geothermal Development Co. (GDC), a state-owned special-purpose vehicle tasked with accelerating the nation’s geothermal resource development, expanded its focus to the Menengai region just north of Olkaria, at the site of a massive shield volcano with one of the biggest calderas in the world. While GDC says the Menengai complex harbors a potential of 1,600 MW, its long-term goal is to develop 465 MW of geothermal steam equivalent.

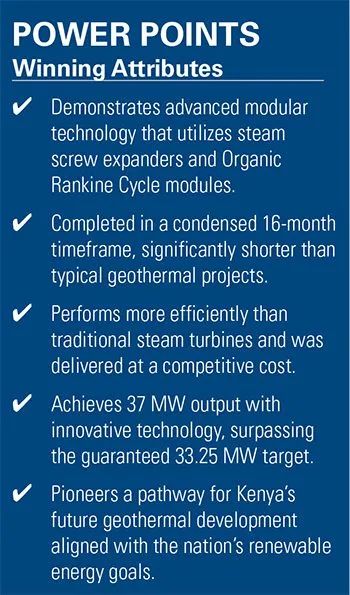

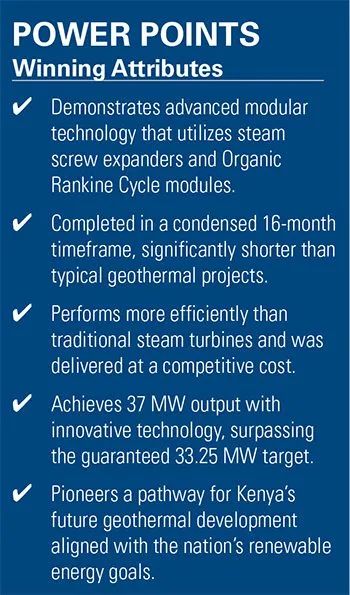

In 2013, it took the first step to competitively award the first three initial 35-MW power projects at the complex to three independent power producers (IPPs): Orpower 22 (a former subsidiary of New York firm Symbion now owned by China’s Kaishan Group), South African-based Quantum Power East Africa (now majority owned by UK firm Globeleq), and Nairobi-headquartered Sosian Energy. In August 2023, the first of these projects—Menengai III, now formally known as the Sosian Menengai Geothermal Power—wrapped up a 16-month construction timeframe and began delivering first power to the grid.

Map showing location of geothermal area along the Kenyan Rift Valley. Courtesy: KenGen

A Technology Breakthrough

Sosian’s condensed timeframe is especially stunning given that traditional geothermal development can exceed seven years. This is owing in part to a complex process that involves drilling and testing multiple wells, selecting a centralized power plant location, ordering steam turbines, and constructing extensive steam collection and reinjection systems. The traditional approach is also ridden with risks, including significant delays and inefficiencies, such as energy losses from steam pressure drops, thermal losses over long distances, and the underutilization of wells with varying pressures.

Sosian, to some measure, had the benefit of the GDC’s public-private partnership model for developing Menengai, under which the GDC assumes upfront risks of geothermal development. The state company has also notably set out to develop the field in five phases, starting with a 105-MW “steam sales” model, where it supplies steam from drilled wells to the power plants via a 25-km steam gathering and piping system. As of 2023, GDC had drilled 53 wells with a potential of 169 MW.

However, the power plant’s success can also be attributed to a distinctive new geothermal development process introduced by China’s Kaishan Group. Dr. Tang Yan, general manager of Kaishan Group, recalled realizing the need for a dramatic shift at a 2015 geothermal conference in Melbourne, Australia, where experts discussed the pitfalls of conventional methods. “I said, ‘Why don’t you put a power plant on the wellhead and do it phase by phase?’ ” he recounted.

Overcoming Traditional Challenges

While the approach proposed to support incremental power production from the start while providing revenue to support future project expansion, Yan learned no technology to support the approach was commercially available. Kaishan, which had then already begun its transition from a giant Shanghai-headquartered air compressor maker to a diversified global company, jumped into action to leverage its 2012-developed Organic Rankine Cycle (ORC) expander and screw steam expander technologies.

The technologies—originally developed for waste heat recovery from refineries and steel mills—allowed Kaishan to optimize geothermal power generation by maximizing energy output from varying well conditions, reducing inefficiencies, and enabling the development of four types of decentralized, modular power plants that are quicker to deploy and more adaptable to different geothermal fields, Yan told POWER. “These modular power plants include the steam screw expander modular power plants, the steam ORC modular power plants, the brine ORC modular power plants, and the steam and brine dual resource modular power plants,” he explained.

Steam screw expanders are specifically designed to handle wet or saturated steam, which is common in geothermal wells, effectively extracting energy from a wider range of well conditions, including wells with high non-condensable gas (NCG) content that may not be suitable for traditional turbines. ORC systems, meanwhile, are adept at converting lower-temperature steam and brine—byproducts that would otherwise go to waste—into additional electricity, Yan said.

In addition, Kaishan’s modular plants can be used to form hybrid cycles or thermal systems to meet any production well conditions, maximize their power output, and eliminate low-head pressure (WHP) wasted wells or idling wells. Because the technologies can be adapted to specific geothermal resource conditions at different project sites, they can be tailored to provide stellar efficiency, he said. “We can improve the well thermal efficiency of, for example, medium enthalpy wells, to up to 18% and 19%,” he said. That compares to only 8% to 12% for traditional centralized power plants that only use single-flash steam, he noted.

he 35-MWe Sosian Menengai Geothermal Power plant was commissioned in August 2023. The plant uses two Kaishan geothermal steam counterpressure screw expanders, which discharge their exhausts into three Organic Rankine Cycle units. Courtesy: Kaishan Group

A Competitive Edge for New Geothermal Power

Kaishan quickly expanded the niche technology into a lucrative business. Since it put online the first of four phases of the 240-MW Sorik Marapi Geothermal Project in Indonesia in 2018, it has built the 10-MW Sokoria Geothermal, also in Indonesia, alongside projects in Turkey, the U.S., and Hungary. At Sosian, Kaishan’s first project in Kenya, the company served as the engineering, procurement, and construction (EPC) contractor.

According to Yan, Kaishan’s cost-effective price point proved a crucial selection advantage. Kaishan’s EPC contract is valued at $65 million, compared to a $108 million EPC contract recently awarded for Menengai II, one of the region’s three equally sized IPP projects. The price difference is rooted in the technology selection, Yan explained. While Sosian’s 35-MW project was designed as a centralized power plant, it is powered by two steam screw expanders and three wet steam ORC modular power plants.

However, GDC’s steam contains 3.3% NCG—which represents a “huge percentage,” he said. If Sosian used traditional steam turbines, they would need to expand steam at 6 bar absolute and then consume more then 30 tons of steam per hour to remove NCG using steam injectors and vacuum pumps. Instead, Sosian employs steam screw expanders and a bottom cycle to handle the saturated steam discharge, reducing the steam to atmospheric levels throughout the entire process while eliminating the parasitic power typically consumed by vacuum systems.

“The overall efficiency compared to a traditional steam turbine is a huge game changer for this site,” Yan said. “The project only needed a guarantee of 33.25 MW, and the target was 35 MW, but we’re actually generating 37 MW.” At the same time, the project doesn’t need to purchase the extra 10% of steam for a steam injector, putting less of a burden on the GDC, he said.

A Solution for Idled Wells

The modularity of the system also proved beneficial to speed up construction and, crucially, to overcome supply chain and project management challenges posed by the COVID pandemic, Yan said. Kaishan typically assembles the modules and conducts component testing in a factory setting over six to nine months, he said. “And then, when we ship to the site, usually it takes a very short time to put them together, and you don’t need to do any welding on the power modules,” he added. “That’s sometimes where quality control can be a challenge,” he noted.

The success of the Sosian Menegai project has so far sparked significant interest in Kenya’s geothermal industry, Yan said. A key reason is that Kenya has a lot of wells, and an estimated 25% to 30% of those wells may not be supported by a steam collection system, which is needed by centralized steam turbines. “They call them idled wells or wasted wells, and they sit there and do nothing,” even if it was costly to drill them, he said. “But our technology doesn’t have that limitation because we can use any good pressure, whether they can produce brine or steam.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).

中文翻譯稿

模塊化發電廠正在提高肯尼亞地熱效率

調試階段的 Sosian Menegai。圖片來源:開山集團

肯尼亞最新的地熱發電廠 Sosian Menengai 地熱發電廠采用模塊化技術,可最大限度提高效率、降低成本并增強可擴展性。

肯尼亞風景秀麗的裂谷地區是地熱資源的寶庫。肯尼亞裂谷是廣闊的東非大裂谷系統 (EARS) 的一部分,東非大裂谷系統是一個長達 6,400 公里的地質構造分叉,將非洲大陸一分為二。肯尼亞裂谷形成了一個垂直走廊,其中有密集的斷層和火山活動、溫泉、噴氣孔和硫磺滲出的裂縫。盡管肯尼亞在 20 世紀 50 年代就開始進行地熱勘探以開發電力,但其大部分投資都集中在位于地獄之門國家公園內的奧爾卡里亞地區,該公園靠近納庫魯縣火烈鳥點綴的納瓦沙湖。奧爾卡里亞的六座地熱發電站中有五座歸 KenGen 所有(總容量為 799 兆瓦),而總部位于內華達州的 Ormat Technologies擁有一座 150 兆瓦的發電站。到 2023 年,奧爾卡里亞 (Olkaria) 電廠將提供肯尼亞近 45% 的總發電量,為這個東非強國僅有的 3.3 吉瓦的裝機容量做出了巨大貢獻。

2008 年,地熱開發公司 (GDC) 將重點擴大到奧爾卡里亞以北的梅嫩蓋地區,該地區是一座巨大的盾形火山,擁有世界上最大的火山口之一。地熱開發公司是一家國有特殊目的公司,其任務是加速該國的地熱資源開發。GDC 表示,梅嫩蓋綜合體蘊藏著 1,600 兆瓦的地熱潛力,但其長期目標是開發 465 兆瓦的地熱蒸汽當量。

2013 年,該集團邁出了第一步,通過競爭方式將該綜合體中的前三個 35 兆瓦發電項目授予三家獨立電力供應商 (IPP):Orpower 22(前身為紐約 Symbion 公司的子公司,現歸中國開山集團所有)、總部位于南非的 Quantum Power East Africa(現由英國公司 Globeleq 控股)和總部位于內羅畢的 Sosian Energy。2023 年 8 月,這些項目中的第一個項目——Menengai III(現正式稱為 Sosian Menengai 地熱發電項目)結束了為期 16 個月的建設工期,并開始向電網輸送第一批電力。

地圖顯示了肯尼亞裂谷沿線地熱區的位置。圖片來源:KenGen

技術突破

鑒于傳統地熱開發可能要耗時超過七年,Sosian 的縮短工期尤其令人震驚。這在一定程度上歸因于一個復雜的過程,包括鉆探和測試多個井、選擇集中發電廠位置、訂購蒸汽渦輪機以及建造廣泛的蒸汽收集和再注入系統。傳統方法也充滿風險,包括嚴重的延誤和效率低下,例如蒸汽壓力下降造成的能量損失、長距離熱損失以及壓力變化的井的利用不足。

在某種程度上,Sosian 受益于 GDC 開發 Menengai 的公私合作模式,根據該模式,GDC 承擔地熱開發的前期風險。值得注意的是,這家國有公司還計劃分五個階段開發該地熱田,首先采用 105 兆瓦的“蒸汽銷售”模式,通過 25 公里長的蒸汽收集和管道系統將鉆井中的蒸汽供應給發電廠。截至 2023 年,GDC 已鉆探了 53 口井,潛力為 169 兆瓦。

然而,該發電廠的成功也歸功于中國開山集團推出的獨特的新型地熱開發工藝。開山集團總經理湯炎博士回憶說,他在 2015 年澳大利亞墨爾本舉行的地熱會議上意識到需要進行重大轉變,當時專家們討論了傳統方法的缺陷。“我說,‘你為什么不在井口建一個發電廠,分階段進行呢?’”他回憶道。

克服傳統挑戰

雖然該方法從一開始就提出支持增量發電,同時提供收入以支持未來的項目擴展,但湯炎博士了解到,沒有支持該方法的技術可供商業使用。開山當時已經開始從一家總部位于上海的大型空氣壓縮機制造商轉型為一家多元化的全球性公司,并立即采取行動,利用其 2012 年開發的有機朗肯循環 (ORC) 膨脹機和螺桿蒸汽膨脹機技術。

湯炎博士告訴《POWER》雜志,這些技術最初是為回收煉油廠和鋼廠的廢熱而開發的,它使開山公司能夠通過最大限度地提高不同井況下的能量輸出、減少低效率,以及開發四種類型的分散式模塊化發電廠來優化地熱發電,這些發電廠部署速度更快,更能適應不同的地熱田。 “這些模塊化發電廠包括蒸汽螺桿膨脹機模塊化發電廠、蒸汽 ORC 模塊化發電廠、鹽水 ORC 模塊化發電廠以及蒸汽和鹽水雙資源模塊化發電廠,”他解釋說。

蒸汽螺桿膨脹機專門設計用于處理地熱井中常見的濕蒸汽或飽和蒸汽,可有效從各種井況中提取能量,包括可能不適合傳統渦輪機的不凝性氣體 (NCG)含量高的井。與此同時,ORC 系統擅長將低溫蒸汽和鹽水(否則這些副產品將被浪費)轉化為額外的電能,湯炎博士說。

此外,開山的模塊化電廠可用于形成混合循環或熱力系統,以滿足任何生產井條件,最大限度地提高其發電量,并消除低壓 (WHP) 浪費井或閑置井。他說,由于這些技術可以適應不同項目地點的特定地熱資源條件,因此可以量身定制以提供卓越的效率。他說:“我們可以將中焓井的熱效率提高到 18% 和 19%。”他指出,相比之下,僅使用單次閃蒸蒸汽的傳統集中式發電廠的熱效率僅為 8% 至 12%。

35 MWe 的 Sosian Menengai 地熱發電廠于 2023 年 8 月投入使用。該電廠使用兩臺開山地熱蒸汽反壓螺桿膨脹機,將廢氣排放到三個有機朗肯循環裝置中。圖片來源:開山集團

新地熱發電的競爭優勢

開山迅速將這項小眾技術拓展為一項利潤豐厚的業務。自2018 年在印度尼西亞投產 240 兆瓦 Sorik Marapi 地熱項目四期工程中的第一期以來,該公司已在印度尼西亞建造了 10 兆瓦的 Sokoria 地熱項目,此外還在土耳其、美國和匈牙利開展了項目。Sosian是開山在肯尼亞的第一個地熱項目,公司擔任工程、采購和施工 (EPC) 承包商。

湯炎博士表示,開山電廠具有成本效益的價格點是其關鍵的選擇優勢。開山電廠的 EPC 合同價值 6500 萬美元,而該地區三個同等規模的 IPP 項目之一 Menengai II 最近獲得的 EPC 合同價值 1.08 億美元。湯炎博士解釋說,價格差異的根源在于技術選擇。雖然 Sosian 的 35 兆瓦項目設計為集中式發電廠,但它由兩個蒸汽螺桿膨脹機和三個濕蒸汽 ORC 模塊化發電廠提供動力。

然而,GDC 的蒸汽含有 3.3% 的 NCG,這是一個“巨大的百分比”,他說。如果 Sosian 使用傳統的蒸汽輪機,他們需要將蒸汽膨脹至 6 bar 絕對壓力,然后每小時消耗超過 30 噸的蒸汽,使用蒸汽噴射器和真空泵去除 NCG。相反,Sosian 使用蒸汽螺桿膨脹機和底部循環來處理飽和蒸汽排放,在整個過程中將蒸汽降低到大氣水平,同時消除真空系統通常消耗的寄生功率。

“與傳統蒸汽輪機相比,整體效率對于該站點來說是一個巨大的改變,”湯炎博士說道。“該項目只需要保證 33.25 兆瓦,目標是 35 兆瓦,但我們實際上發電量為 37 兆瓦。”同時,該項目不需要額外購買10%的蒸汽用于蒸汽噴射器,從而減輕了GDC的負擔,他說。

閑置地熱井的解決方案

湯炎博士表示,該系統的模塊化設計也有利于加快施工速度,更重要的是,有助于克服新冠疫情帶來的供應鏈和項目管理挑戰。他說,開山通常會在六到九個月的時間內組裝模塊并在工廠環境中進行組件測試。“然后,當我們運送到現場時,通常只需很短的時間即可將它們組裝在一起,并且您無需對電源模塊進行任何焊接,”他補充道。“有時,質量控制可能是一個挑戰,”他指出。

他還說,Sosian Menegai 項目的成功迄今已引起人們對肯尼亞地熱產業的極大興趣。一個關鍵原因是肯尼亞有很多井,估計其中 25% 到 30% 的井可能沒有蒸汽收集系統,而蒸汽收集系統是集中式蒸汽渦輪機所必需的。“他們稱這些井為閑置井或廢棄井,它們就放在那里,什么也不做”,即使鉆探這些井的成本很高,“但我們的技術沒有這種限制,因為我們可以使用任何良好的壓力,無論它們是產生鹽水還是蒸汽。”

— Sonal Patel 是 POWER 的高級編輯(@sonalcpatel, @POWERmagazine)